With governments across the globe setting challenging net-zero emissions targets and businesses looking to maintain a social licence to operate, it’s now time for action.

In 2019 the UK government set a net zero emissions target for the year 2050, with the Scottish Government announcing an even tighter timescale of 2045. To achieve these ambitious net zero targets the UK government has outlined a ten point plan which will have a significant impact on a number of industries, including the distilling sector which will be required to play its part in energy transition.

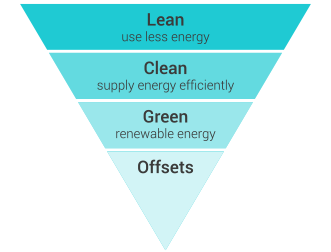

The approach to developing a net zero future for the scotch whisky sector has been guided by a hierarchy of sustainable energy measures. A focus on Lean, Clean & Green will ensure that a sustainable approach is prioritised and carbon offsets are only used once all other options have been exhausted.

With an intimate knowledge of the distilled spirit production process, Allen Associates’ team of experienced design engineers has been helping distillers deliver projects which have had significant impact on these Lean, Clean & Green energy measures. As technology and processes have improved the company has stayed at the forefront of sustainable distilling, leading the industry as it pursues a transition away from fossil fuels.

Our Services

Allen Associates can provide Lean, Clean & Green solutions throughout the distilling process:

- Net zero emissions planning – working with distillers to develop a road map to achieve net zero emissions which can also ensure strategic business decisions are carbon resilient

- Energy transition planning - working with distillers on options for developing projects for the transition away from fossil fuels to hydrogen and electricity*

- Energy audits – ESOS Lead assessors from the Institute of Chemical Engineers with ISO standard auditing

- Modelling technology - advanced proprietary distillery energy modelling software to assist with energy audits and project identification

- Project appraisal - feasibility studies, capex, opex, pay-pack calculation, KPI impact.

- Delivery of full project including energy efficient process design & installation

- Utilisation of Pinch technology

Specialist Systems

Over the years Allen Associates has designed and installed a range of energy savings systems, including:

- Heat pumps, including the industry changing Greenstills system*

- Condenser hot water recovery systems

- Thermal Vapour Recompression (TVR) systems

- Pot ale & spent lees heat recovery systems

- Flash steam recovery systems

- High gravity mashing systems

- Boiler economisers

*Working with key suppliers Allen Associates created Greenstills through the combination of a condenser hot water recovery system and a high temperature heat pump. Joining the two systems can result in ~70% savings in energy, a reduction in C02 emissions and an energy transition pathway to a highly efficient all electric distillery.

Some projects that contributed to that saving are:

- Tamdhu (condenser HR system)

- Macallan (flash recovery system)

- Glenrothes (boiler economiser)

- Craigellachie (worm tub HR system)

- Aultmore (flash recovery system)

- Royal Brackla (low wines & feintspre-heating system)

- Aberfeldy (low wines & feints pre-heating system)

- Glenmorangie (condenser HR system)

- Ardbeg (condenser HR system – being installed)

- Glen Grant (condenser HR system)

- Old Pulteney (low wines & feints pre-heating system)

- Balmenach (low wines & feints pre-heating system)

- Speyburn (worm tub HR system)

- Knockdhu (low wines & feints pre-heating system)

- Balblair (condenser HR system)

- Dufftown (boiler economiser)

- Tullamore Dew (condenser HR & TVR system)

- Bowmore (low wines & feints pre-heating system)